Flexaseal

Slurry Seals

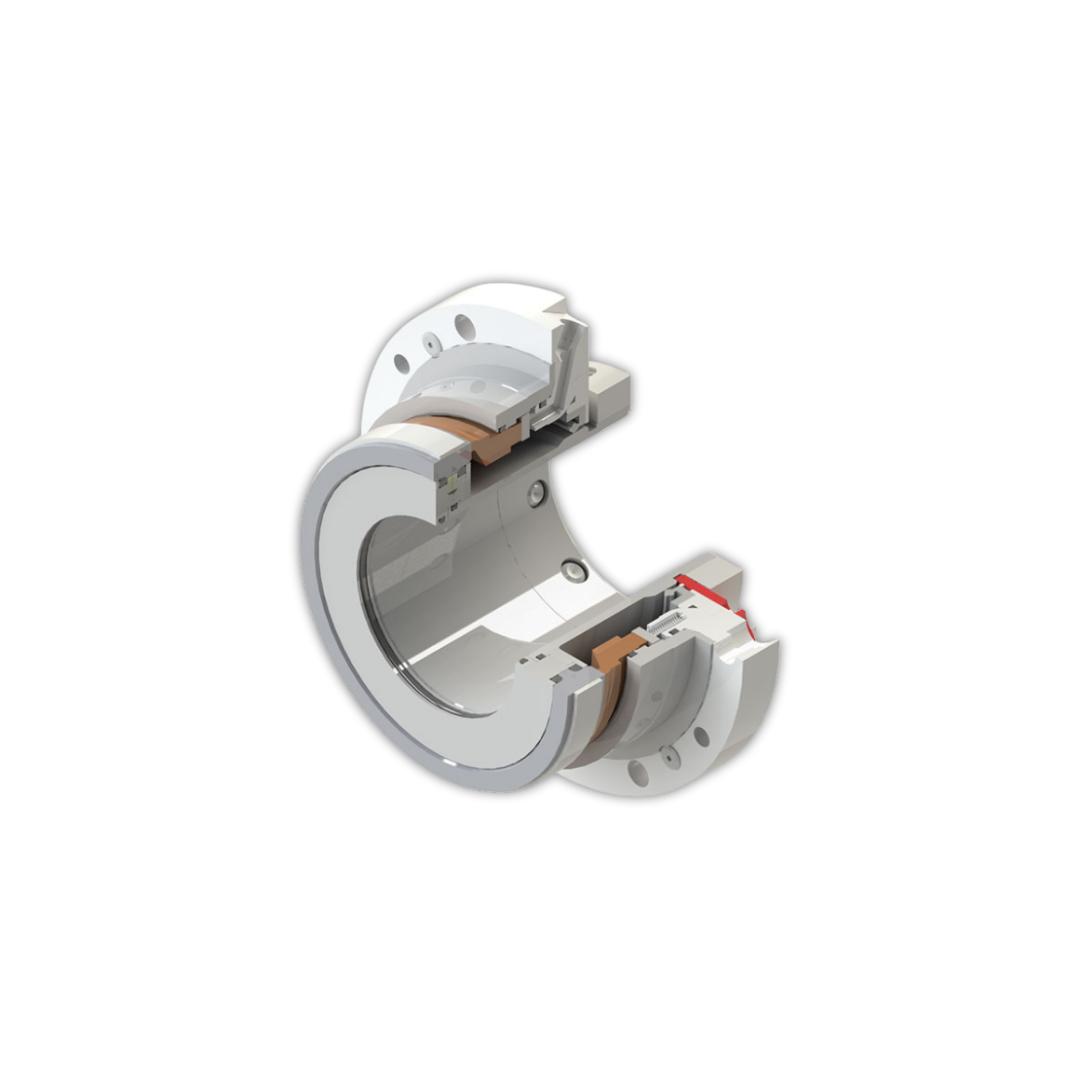

Flushless Slurry Seals Built for the Toughest Pumping Environments

Flexaseal’s RKC Series slurry mechanical seals are engineered to perform under the most punishing conditions found in mining, mineral processing, flue gas desulfurization (FGD), and other abrasive, high-solids applications. Designed for durability and efficiency, these heavy-duty seals deliver long-lasting reliability, without the need for external flushing.

The RKCS single cartridge seal and RKCD dual cartridge seal are easy to maintain and built to handle extreme operating conditions. Available in four unique configurations, each model incorporates robust features like reverse pressure sealing, non-clogging spring designs, and hydraulically balanced seal faces, ensuring consistent performance in highly abrasive and corrosive environments.

Slurry Seal Specifications

| Category | Details |

|---|---|

| Seal Faces | Ni-B Tungsten Carbide, Sintered Silicon Carbide, Graphite-Loaded Silicon Carbide |

| Elastomers | Standard FKM (other materials available upon request) |

| Springs | Alloy C276 |

| Metal Components | 316 Stainless Steel, Alloy 255, or High-Chrome Iron (wetted parts) |

| Custom Materials | Additional materials available to suit specific process requirements |

Features

- Zero flush design for water and cost savings

-

Simplified cartridge installation and maintenance

-

Handles viscous, high-solid slurries with ease

-

Multi-spring design resists clogging and buildup

-

Engineered for high pressure, speed, and temperature operation

-

Tough materials built to resist erosion and chemical attack

Operating Parameters

- Shaft Sizes: Up to 20.0″ (508 mm)

-

Pressure: Up to 500 psi (34.5 bar)

-

Temperature Range: -4°F to 425°F (-20°C to 218°C)

-

Speed: Up to 3600 fpm (18.3 m/s)

-

Viscosity: Up to 2500 cP

typical applications

- Mining & Mineral Processing

-

Hard Rock Mining

-

Coal Preparation

-

FGD Systems

-

Ore Mining

-

Industrial

-

Aggregates