Flexaseal

Split Cartridge Seals

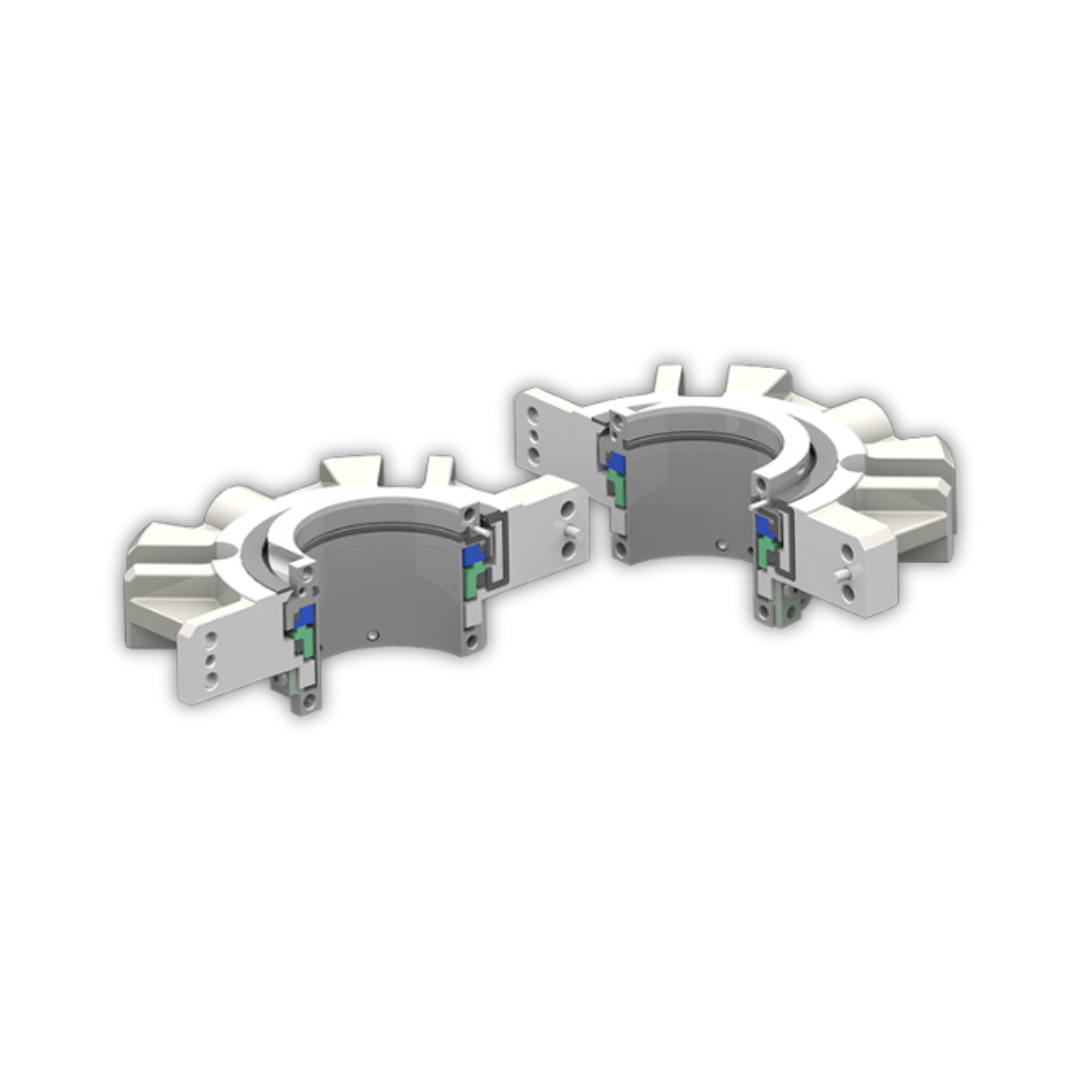

Flexaseal’s split cartridge mechanical seals are engineered to simplify seal replacement while minimizing equipment downtime and eliminating costly disassembly. With just two components to handle, the installation process is fast, safe, and efficient—making these seals an ideal solution for pumps, mixers, and agitators in hard-to-access or time-sensitive applications.

Unlike traditional split seals that require careful face alignment and multiple loose parts, Flexaseal’s design locks both sealing faces securely into the cartridge. This prevents common installation issues like face chipping, misalignment, or damage, ensuring a reliable seal right out of the box.

Features

- True 2-piece design for quick, tool-free installation

-

Factory pre-tested to reduce the chance of installation errors

-

Minimizes equipment tear-down, saving time and maintenance labor

-

Ideal for large shafts, vertical pumps, agitated tanks, and other complex setups

-

Compatible with ANSI and non-ANSI equipment

typical applications

From water and wastewater systems to chemical processing and general industry, Flexaseal’s split cartridge seals are a smart investment in sealing performance and plant productivity. If you’re working with equipment that’s hard to service or expensive to disassemble, these seals offer a cost-effective and dependable solution.

Available Split Seal Styles

| Style | Application |

|---|---|

| 85 | Standard fully split cartridge seal for pumps and rotating equipment |

| 85M | Mixer and agitator version for vertical shafts and side-entry installations |

Each split seal is factory-assembled and pressure-tested before shipment, so you can install with confidence.