Choosing the Right Pump for Your Application

When it comes to fluid handling systems, choosing the right pump for your application is critical to performance and long-term reliability. At Carl Eric Johnson Co. (CEJCO), we understand that no two applications are the same, and neither are the pumps that power them.

With decades of experience across a wide range of industries, CEJCO is here to break down the core differences between centrifugal and positive displacement pumps and help you understand how factors like fluid type, viscosity, and flow requirements impact your decision.

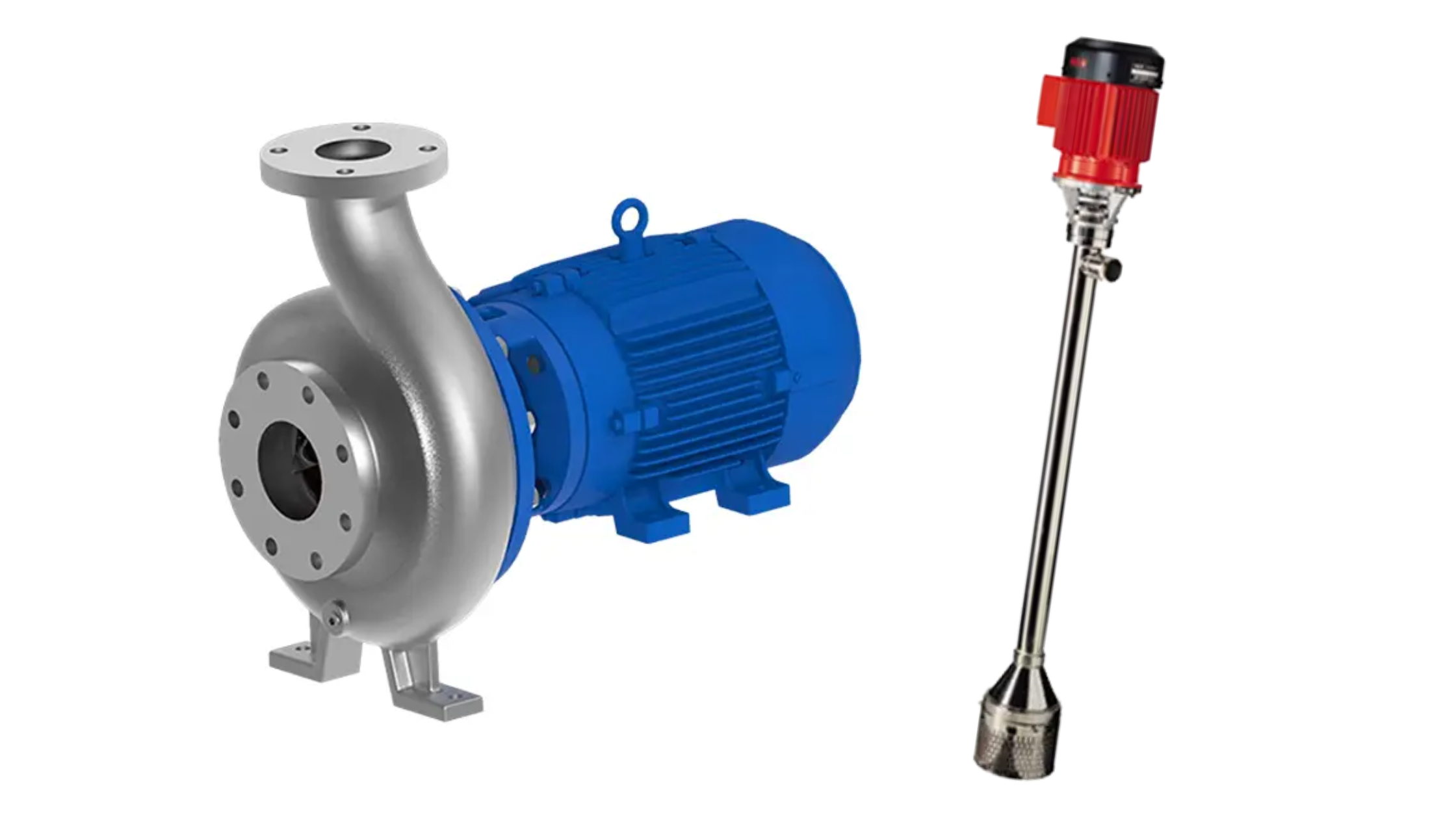

Centrifugal Pumps

Best for Low-Viscosity, High-Flow Applications

Centrifugal pumps use an impeller to generate velocity and pressure, making them ideal for moving low-viscosity fluids like water, light oils, and chemicals.

When to Choose a Centrifugal Pump:

- You’re pumping clean, non-viscous fluids

- You need high flow rates

- The system pressure is relatively constant

- You want lower upfront costs and easy maintenance

Common Applications:

- Water treatment

- HVAC systems

- Chemical transfer

- General industrial use

Positive Displacement Pumps

BUILT FOR THICK, HIGH-PRESSURE TASKS

Unlike centrifugal pumps, positive displacement (PD) pumps move fluid by trapping a fixed amount and forcing it through the system. This makes them ideal for viscous, abrasive, or shear-sensitive fluids.

When to Choose a Positive Displacement Pump:

- You’re handling high-viscosity fluids like molasses, slurries, or polymers

- You need to maintain a consistent flow, even at high pressures

- Your system requires accurate metering or dosing

Common Positive Displacement Pump Types We Offer:

- Gear Pumps

- Diaphragm Pumps

- Peristaltic Pumps

- Progressive Cavity Pumps

Consider Your Fluid Properties

The physical and chemical properties of your fluid will greatly influence the type of pump you need. Our team helps customers evaluate:

- Viscosity: How thick is your fluid? Thicker fluids usually require Positive Displacement pumps.

- Solids Content: Does your fluid contain particulates? If so, impeller clearance and wear must be considered.

- Corrosiveness: Are you handling acids, solvents, or harsh chemicals? CEJCO offers pumps with chemically resistant materials like Teflon, Hastelloy, and more.

- Shear Sensitivity: Products like emulsions or biological fluids require gentle handling to prevent damage.

Flow Rate and Pressure

- Flow Rate (GPM or LPM): This defines how much fluid you need to move per minute.

- Discharge Pressure: This is the force the pump must overcome in the system.

- Net Positive Suction Head (NPSH): Critical for avoiding cavitation in centrifugal pumps.

At CEJCO, we help you size pumps accurately using performance curves, system specifications, and real-world operating conditions.

Need Help?

Selecting the wrong pump can lead to costly downtime, poor performance, or premature failure. That’s why our team of experienced engineers works with you one-on-one to recommend and supply the right solution—every time.

Whether you need a rugged pump for chemical processing or a sanitary solution for food and beverage, CEJCO has you covered.

Get Started Today

Let us help you take the guesswork out of pump selection. Contact CEJCO today for technical support, product availability, or a customized fluid handling solution.