moyno

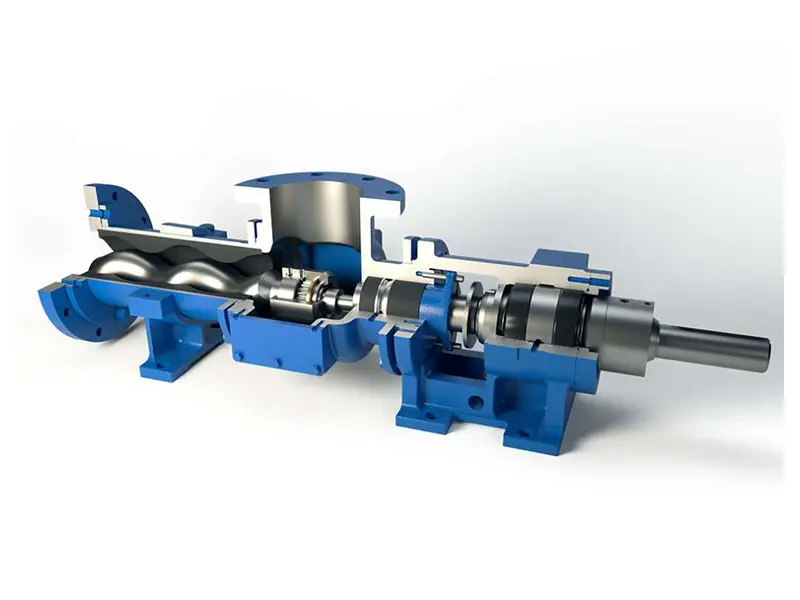

2000 pump

The 2000 pumps set the standard is positive displacement pumping applications. Featuring a unique gear-type universal joint design, the proprietary 2000 design manages both radial and thrust loads, ensuring optimal performance and extended lifespan.

These robust pumps excel at managing abrasive materials exceeding 80% solids, providing a performance range up to 4,500 GPM and pressure capabilities reaching 1,500 PSI.

benefits

- Gear Joint Design: Uniform design of the ring gear and gear call components create greater surface contact leading to less wear

- Available in cast iron or stainless steel, with your choice of rotar/stator materials to meet you application requirements

- Low Running Speeds: Reduced wear for longer working pump life

- Reduces shear and crush damage to the product; maintains a steady flow when pumping high solid content

- Fiber deflector prevents ragging around the connecting rod and rotor head

- Shaft sleeve protects the drive shaft from highly abrasive application wear

specifications

-

Capacity: up to 2,100 gal/min

-

Pressure: up to 1,500 psi

-

Temperature: 14F up to 230F

applications

- Sewage lift station & headworks

- Primary & tertiary sedimentation

- Grit removal

- Nitrification

- Thickening & conditioning

- Dewatering

- Multiple fluid transfer

- Lease automatic custody transfer

- Adhesives

- Slurries

- Chemical metering

- Polymer

- Food & beverage processing

- Starches, slurries, and coatings

- Leaching / neutralization

- Flocculants

moyno

G1 – FLANGED DESIGN

The high-performing 2000 Pumps provide a low-maintenance solution, minimizing downtime and ensuring a prolonged service life, all contributing to a cost-effective ownership experience.

Benefits

-

Fluid Type: Broad range of viscosities & solids

-

Fluid Supply: Standard Pipe

-

Benefits: Greatest Value for majority of applications

applications

-

Oil

-

Polymers

-

Municipal sludge to 10% solids

-

Titanium Dioxide

-

Paper coatings

-

Mining Slurries

moyno

G2 – Single Auger Feed

The 2000 Pumps deliver superior performance, requiring minimal maintenance, downtime, and boast an extended service life.

Benefits

- Single auger feed device to stuff product into the pump elements for increased fill efficiency

- Wide open-throat minimizes plugging that could occur in a standard inlet

specifications

-

Fluid Type: Viscosity and solids; open inlet is needed

-

Fluid Supply: Wide open-throats and chutes

-

Suitable for varying length to match wide feed areas.

-

Centrifuges and 1, 1.5, & 2-meter length belt filter presses

applications

- Heavy clay slurriesGypsum

- Grout

- Grape must

- Municipal GBT sludge

- Municipal sludge to 15% solids

- Thick industrial sludges

moyno

G3 – Bridge Breaker

The 2000 Pumps, known for their exceptional performance, provide a low-maintenance solution with minimal downtime and an extended service life, resulting in a cost-effective total ownership experience.

Benefits

- The Moyno bridge breaker, independently driven, offers the flexibility to operate at varying RPMs distinct from the pump

- A single auger feed mechanism is utilized to push the product into the pump elements, enhancing fill efficiency

- Open-throat design significantly reduces the risk of plugging commonly associated with standard inlets

specifications

- Fluid Type: Medium to high-viscosity and solids where product bridging is a concern

- Fluid Supply: Via wide open-throats and chutes

- Capable of varying length to match wide feed areas from centrifuges and 1, 1.5, and 2-meter length belt filter presses

applications

- Pharmaceutical pastes

- Heavy petroleum sludges

- Plasticizers

- Municipal sludge in excess of 30% solids

- Paper stock in excess of 12% solids

moyno

G4 – 45 Inlet Design

The G4 progressing cavity pump, designed for high efficiency, incorporates a 45° inlet to reduce friction loss and facilitate a gentler handling of the product.

Benefits

- The universal joint is positioned outside the fluid flow path, ensuring unobstructed flow to the pump cavity inlet.

- Lower overall system pressure

- Constant, non-pulsating flow imparts less stress on piping machinery and drive systems

- Patented auger feed on the rotor head smoothly stuffs product directly into the cavity without obstruction

- Rotor configuration is designed to enhance flow of high solids content materials and optimize volumetric efficiency

specifications

- Fluid Type: High Solids

applications

- Pharmaceutical pastes

- Heavy petroleum sludges

- Plasticizers

- Municipal sludge in excess of 30% solids

- Paper stock in excess of 12% solids