dickow

mag-drive pumps

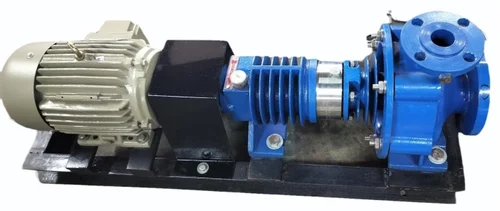

KM Series

The KM series of pumps by DICKOW are centrifugal pumps designed without seals. Their static containment shell creates a sealed system with a hermetically sealed liquid end. The AMB model pumps are compatible with ANSI casing dimensions.

Applications

The magnetic-driven KM pumps are engineered to enhance safety for both plant facilities and personnel. This is particularly crucial when dealing with hazardous liquids that are toxic, explosive, or reactive upon exposure to the atmosphere. These pumps operate without the need for maintenance, and their containment shells serve as replacements for double-acting mechanisms.

Dickow

NM Series

The NMB/NML series of DICKOW pumps, utilizing magnetic coupling, feature a sealless design. The containment shell establishes a sealed system in conjunction with a hermetically sealed liquid end.

Applications

NM pumps, propelled by magnets, are engineered to enhance safety for both plant facilities and personnel, particularly in scenarios involving toxic, explosive, or reactive liquids upon exposure to the atmosphere. These pumps offer significant advantages to industries such as chemicals, petrochemicals, and related sectors by replacing double-acting mechanical seals, external fluid reservoirs, and associated control equipment with the containment shell. They also comply with environmental protection regulations.

The standard NMB/NML-type pumps can operate at temperatures up to 240°C (465°F), while the NMW design, featuring no internal circulation and a dead-ended magnet end, enables temperatures up to 400°C (750°F). The maximum allowable working pressure is 25 bar (364 psi).

Dickow

NMR Series

DICKOW-Pumps from the NMR series feature a sealless design, employing magnetic coupling. The containment shell creates a sealed system in tandem with a hermetically sealed liquid end. These pumps are specifically engineered for the chemical process industry, utilizing leak-free magnetic drives to enhance safety for both plant facilities and personnel in industrial heating plants.

Applications

NMR pumps, driven by magnets, are engineered to enhance safety in various industrial settings, particularly when handling hazardous liquids that are toxic, explosive, or reactive with the atmosphere. By replacing double-acting mechanical seals, along with external fluid reservoirs and necessary control equipment, with the containment shell, these pumps offer significant advantages to the chemical, petrochemical, and related industries. They also ensure compliance with environmental protection regulations.

Dickow

NMW/PRMW

The NMW/PRMW series of DICKOW pumps, utilizing magnetic coupling, feature a sealless design where the containment shell creates a closed system with a hermetically sealed liquid end.

Applications

These magnetic-driven NMW/PRMW pumps are specifically engineered for hot oil applications, aiming to enhance safety for both plant facilities and personnel in industrial heating plants. By eliminating mechanical seals, they remove the need for utility cooling, a requirement in conventional pumps that utilize double mechanical seals in such scenarios.

Dickow

SCM

The SCM pump by DICKOW is a self-priming horizontal side-channel pump, available in single or multiple stages, featuring a magnet coupling. With its high differential head, this side-channel pump operates more economically than standard centrifugal pumps when dealing with low capacity and high heads. Consequently, side-channel pumps prove to be effective solutions for various pumping challenges encountered in the chemical and petrochemical processes.

The SCM pump is specifically designed as a heavy-duty unit for handling clean fluids without solids. Employing sealless magnetic-driven technology, these pumps significantly enhance safety for both plant operations and personnel, particularly when dealing with hazardous liquids prone to reacting upon contact with the atmosphere. In such applications, the static shroud replaces double-acting mechanical seals, along with external fluid reservoirs or barrier fluid circulating systems. Given that approximately 90% of pump failures and required servicing are attributed to leaking mechanical seals, the sealless design not only reduces maintenance but also lowers spare parts costs considerably, leading to significant total cost savings over the pump’s lifespan.

Dickow

SMV

Side-channel pumps offer self-priming capability and demonstrate superior efficiency compared to standard centrifugal pumps when dealing with low flows and high heads. This efficiency makes them ideal for addressing various pumping challenges encountered in industrial processes. They are suitable for nearly all liquids devoid of abrasive solids and possessing appropriate viscosity.

Vertical side-channel pumps, in particular, are well-suited for tank farms featuring underground storage tanks with a maximum diameter of 2.5 meters (8.2 feet). Their design allows for installation directly on the dome cover, resulting in a suction lift only slightly above the tank diameter and minimizing the length of the priming pipe.

For handling toxic, explosive, and other hazardous liquids in chemical and petrochemical industries, a sealless pump design utilizing permanent magnetic coupling, without a shaft duct to the atmosphere, is also available. With the static containment shell forming a closed system with a hermetically sealed liquid end, these pumps ensure zero leakage during operation. Moreover, they are maintenance-free since no shaft sealing is required.

Dickow

NMT/NCT

The DICKOW® submersible pump, designated as type NCT and tailored for the chemical industry, is a vertical pump featuring a separate discharge pipe. Its maximum capacity reaches up to 700 m³/h, with the option for higher capacities upon request.

Developed specifically for applications in the chemical, petrochemical, and associated industries, the NCT pump type offers versatility through a wide range of materials. This ensures suitability for handling nearly all types of liquids prevalent in these sectors, including acids, alkalis, hydrocarbons, condensation products, solvents, and more.

Dickow

HZSM

DICKOW-Pumps from the HZSM/HZSMA series, employing magnetic coupling, feature a sealless design where the containment shell creates a closed system with a hermetically sealed liquid end. The integrated side channel stage allows for efficient handling of entrained gas and operation under suction lift conditions.

Applications

Magnetic-driven HZSM/HZSMA pumps are engineered to enhance safety for both plant facilities and personnel, particularly when dealing with hazardous liquids that are toxic, explosive, or reactive upon exposure to the atmosphere. By replacing double-acting mechanical seals, along with external fluid reservoirs and necessary control equipment, with the containment shell, these pumps offer significant advantages to the chemical, petrochemical, and related industries while complying with environmental protection regulations.

Dickow

HZMR

The HZMR series of DICKOW® pumps are sealless multistage horizontal centrifugal pumps, propelled by a synchronous permanent magnetic coupling. A confined gasket seals the containment shell, effectively separating the pumped liquid from the atmosphere. This design eliminates the need for dynamic shaft sealing, thus mitigating the risk of leakage.

Given that approximately 90% of pump failures stem from leaking shaft seals, the sealless design not only boosts availability but also slashes maintenance costs.