dickow

process pumps

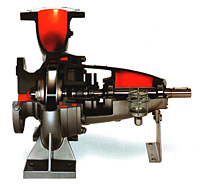

Dickow Pump specializes in supplying sealless metallic centrifugal, multi-stage centrifugal, and side channel pumps with a magnetic coupling. These are available in ANSI, DIN, and fully conform to API 685 standards for sealless centrifugal pumps for petroleum, heavy-duty chemical, and gas industry applications. Conventionally sealed centrifugal, multi-stage centrifugal, side channel and API 610 pumps are also available in DIN and fully conform to many of the API plans. All units are carefully sized and built to the customer’s particular fluid, hydraulic requirements and condition point. Dickow pumps are not mass produced, but rather are manufactured to the highest standards for very specific chemical environments and applications.

Our Marietta, GA location stocks some commonly used pump types and sizes and an extensive array of replacement parts. Our repair facility is able to repair or rebuild any Dickow Pump.

Sealless Magnetic Driven Centrifugal Pumps Type KML/KMB/KMV

Crafted with a focus on enhancing plant and personnel safety, magnetic-driven KM pumps are particularly beneficial when dealing with hazardous substances like toxic, explosive, or reactive liquids exposed to the atmosphere. These pumps operate seamlessly without the need for maintenance, and their containment shells effectively replace double-acting mechanical seals, external fluid reservoirs, and the associated control equipment. The KM pumps boast a maximum capacity of approximately 70 m3/h (300 US-gpm) and a differential head of 65 mLC (213 ft). They can handle a temperature range from -30°C to 200°C (390°F) and operate at a working pressure of 16 bar (232 psi).

Sealless Magnetic Driven Centrifugal Pumps Type NM

Engineered to enhance both plant and personnel safety, magnetic-driven NM pumps prove especially advantageous when handling toxic, explosive, or otherwise hazardous liquids that react upon contact with the atmosphere. The containment shell in NM pumps effectively replaces double-acting mechanical seals, external fluid reservoirs, and the required control equipment for all these applications. As a result, NM pumps offer remarkable benefits to the chemical, petrochemical, and related industries, ensuring compliance with environmental protection regulations. The standard NMB/NML-type achieves a maximum operating temperature of 240°C (465°F), while the NMW-design, featuring no internal circulation and a dead-ended magnet end, permits temperatures up to 400°C (750°F). These pumps are designed to operate under a maximum allowable working pressure of 25 bar (364 psi).

Sealless Magnetic Coupled Centrifugal Pumps Type NMR

Magnetic-driven NMR pumps are crafted with the aim of enhancing both plant and personnel safety, particularly in situations involving toxic, explosive, or otherwise hazardous liquids that react with the atmosphere. The containment shell in NMR pumps effectively substitutes double-acting mechanical seals, external fluid reservoirs, and the required control equipment for all these applications. Consequently, NMR pumps deliver outstanding advantages to the chemical, petrochemical, and related industries, ensuring compliance with all environmental protection regulations.