labour taber

labour taber

LVA

Robust ANSI pump with a durable design, offered in a diverse range of metallurgies. The standard configuration features the industry’s lowest “Shaft Flexibility Factor (L3/D4),” the highest “Basic Dynamic Load Rating” for bearings, a power end L10 life exceeding 100,000 hours, and a “Flinger” oil lubrication system.

The LVA ANSI-compliant pump can manage corrosive, toxic, and abrasive process liquids, including acids, bases, and solvents.

BENEFITS

- The LVA casing features a self-venting, top-centerline discharge with a fully enclosed gasket. It is equipped with dual oil level monitoring systems, including the “Bullseye Sight Glass” and the transparent “Trico® Optimatic” constant level oiler. The pump incorporates two heavy-duty, back-to-back mounted 7300 series angular contact bearings, ensuring an industry-leading L10 life exceeding 100,000 hours.

- With the largest shaft diameter (D) and the shortest impeller overhang (L), it achieves the industry’s lowest “Shaft Flexibility Factor (L3/D4).” The flinger-type lubrication system creates a continuous oil mist over the radial and thrust bearings, resulting in cooler running bearings compared to flooded lubricated bearings from other manufacturers.

- Integral impeller pump-out vanes reduce stuffing box pressure, thereby extending the life of mechanical seals and bearings. For select sizes of Pump Group I, II & III pumps, a Low Flow Impeller is available to enhance Mean Time Between Failures (MTBF) in applications operating close to shut-off on a standard pump.

APPLICATIONS

- Agriculture

- Chemical Transfer

- Petro-Chemical

- Pulp & Paper

- Plastics

- Refining

- Pharmaceutical Plants

SPECIFICATIONS

-

Capacities: Up to 4000 USGpm (900 m3/hr )

-

Head: Up to 728 feet (222 meters)

-

Pressure: Up to 350 psi (2414 kPa)

-

Horsepower: Up to 275 hp (205 kW)

-

Temperature: Up to 500 °F (to 260°C)

-

Drives: Electric Motors, Steam Turbines, Diesel, PTO, VFD, Belts…

-

Liquids: Liquors, alcohols, combustibles, fertilizers, acids, bases, water

-

Materials: Cast or Ductile iron, 316SS(L), 304SS(L), Elcomet K, A48, 317SS, R55, Monel, Nickel, Hastelloy(s), Titanium, Zirconium, plus most machinable alloys.

labour taber

TFA

Sturdy Triple Volute ANSI design incorporating the advanced LVA power end for robust performance. Offers hydraulic balancing of radial loads, making it suitable for challenging applications such as those involving entrained air/gases and viscous liquids. Available in a diverse range of metallurgies.

BENEFITS

- Dual oil level monitoring systems, including the “Bullseye Sight Glass” and the transparent “Trico® Optimatic” constant level oiler, are incorporated. The pump is equipped with two heavy-duty, back-to-back mounted 7300 series angular contact bearings, delivering an industry-leading L10 life exceeding 100,000 hours.

- Featuring the largest shaft diameter (D) and the shortest impeller overhang (L), it achieves the industry’s lowest “Shaft Flexibility Factor (L3/D4).” The flinger-type lubrication system generates a continuous oil mist over the radial and thrust bearings, resulting in cooler running bearings compared to the flooded lubricated bearings of other manufacturers.

APPLICATIONS

- Synthetic Resins and Latex

- Viscous Fluids

- Petrochemicals

- 20% Entrained Air or Vapor

- Vacuum Systems

- Product Transfer

- Industrial Waste

- Heat Transfer

- Acids

SPECIFICATIONS

- Capacities: Up to 1,100 gpm (250 m3/hr)

- Head: Up to 575 feet (175 meters)

- Pressure: Up to 350 psig (25 kg/cm2g, 2,414 kPag)

- Horsepower: Up to 125 hp (93 kW)

- Temperature: From -50 F to 500º F

- Drives: Electric Motors, Steam Turbines, Diesel, PTO, VFD, Belts…

- Liquids: Chemicals, fertilizers, entrained air and all process.

- Materials: Cast or Ductile iron, 316SS(L), 304SS(L), Elcomet K, A48, 317SS, R55, Monel, Nickel, Hastelloy(s), Titanium, Zirconium, plus most machinable alloys.

labour taber

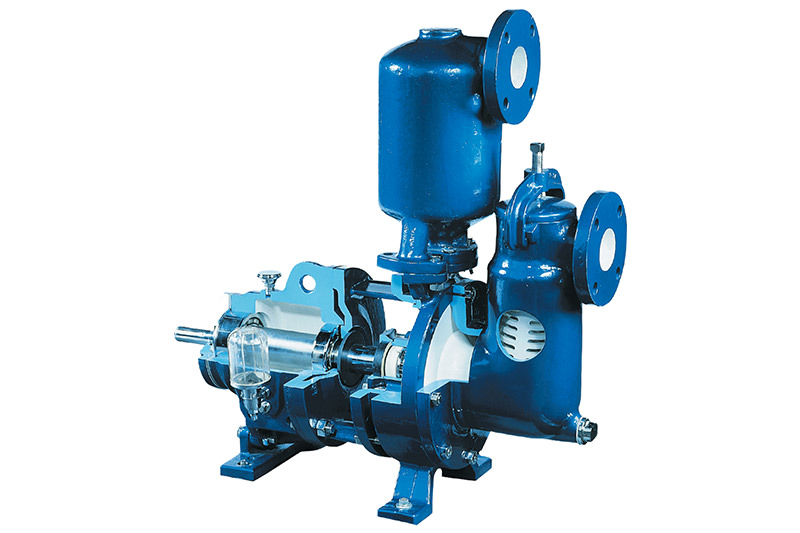

LHLA/LPLA

Utilizing Harry LaBour’s “Hydrobalance” design, this self-priming pump boasts an industry-leading design, ensuring a guaranteed suction lift of 25 ft of H2O at sea level. It also incorporates the same robust power end as the LVA & TFA pumps and is offered in a diverse range of metallurgies.

BENEFITS

- The back pull-out feature includes an ANSI series bearing frame, facilitating maintenance.

- Offers both rapid priming time and high lift capabilities.

- Inherently self-priming, eliminating the necessity for check valves, foot valves, and auxiliary priming devices.

- The LHA/LPLA design integrates large-diameter ANSI shafts, minimizing shaft deflection and reducing mechanical seal wear.

- The circular casing eliminates vapor lock.

- The component construction allows the user to replace individual parts without the need to replace the entire unit.

- A removable basket strainer prevents foreign solids from causing damage to the pump.

APPLICATIONS

- Chemical Transfer

- Bilge Water Removal

- Liquor Evaporator

- Tank Car Unloading

- Industrial Waste Treatment

- Suction Vacuum Systems

- Mine/Tunnel Dewatering

- Excessive Entrained Air

- Condensate Systems

- Volatile Liquid Handling

SPECIFICATIONS

- Capacities: Up to 700 gpm (159 m3/hr)

- Head: Up to 300 feet (91 meters)

- Pressure: Up to 150 psig (11 kg/cm2g, 1,034 kPag)

- Horsepower: Up to 125 hp (93 kW)

- Temperature: Up to 400° F

- Drives: Electric Motors, Steam Turbines, Diesel, PTO, VFD, Belts

- Liquids: Chemicals, condensate systems, entrained air and all process.

- Materials: Cast or ductile iron, 316 SS, A48, 317 SS, R55, Nickel, Elcomet K, Hastelloy(s), Titanium, Zirconium, plus most machinable alloys.