LEWA

process pumps

Leading clients across diverse sectors, spanning crude oil extraction to pharmaceutical manufacturing, rely on LEWA process pumps for high-pressure operations and large-volume pumping needs. Leveraging components from LEWA’s trusted modular system, they tailor process pumps to suit your specific application requirements.

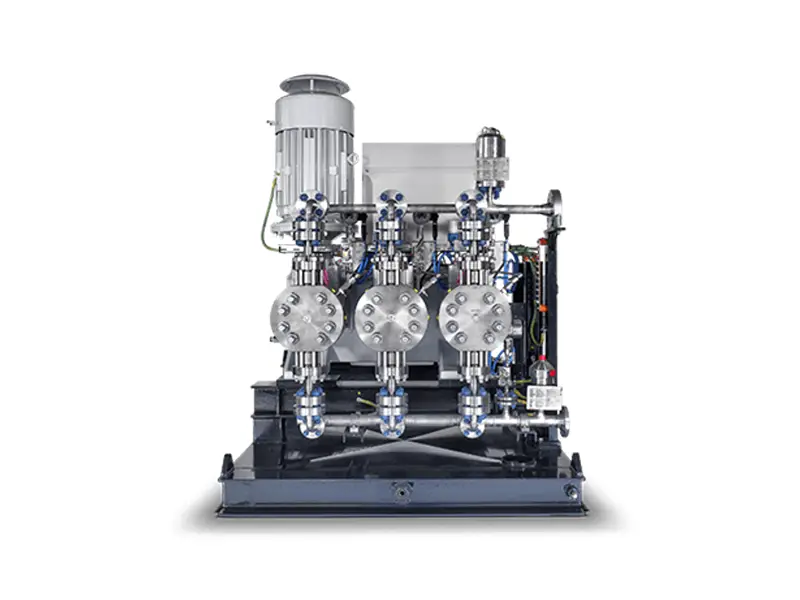

Triplex

process pumps for high-pressure processes

Benefits

- Solid, compact design

- Low—pulsation flow rate

- Unique suction capability

- Safe and reliable in extreme operating states

- Suitable of virtually all fluids

- Patented sandwich diaphragm

- Integrated pressure relief valve

- Vertical flange motor

- API 675 standard

- High energy efficiency

- Low maintenance costs and a long service life

- Hermetically sealed

FEATURES

- hydraulically actuated diaphragm process pump

- LEWA triplex represents robust process diaphragm pumps equipped with the patented LEWA DPS diaphragm protection system. It provides an optimal solution for high-pressure processes across various industries and with a diverse range of fluids. The space-saving monoblock design makes it particularly well-suited for installations with limited space.

- Compact, rugged, reliable.

- Found in the oil and gas industry, chemical industry, food industry, and the energy sector, the LEWA triplex diaphragm process pump is extensively employed in high-pressure applications.

- This pump incorporates proven, patented LEWA diaphragm technology, ensuring secure and reliable operation. Notably, it boasts the world’s most compact design for a process pump, coupled with the advantages of a long service life, minimal life cycle costs, and high energy efficiency.

- Available in six different sizes, this pump is versatile, enabling its use across a diverse range of processes and applications while meeting various requirements.

- Facilitates optimal heat transfer by generating a scouring action that combats fouling or scaling

- Fits into 20–50% of a shell and tube footprint

- A wide selection of plate styles, patterns, and draw depths are available to meet the requirements of your application

- Temperatures: Of less than 1°C (2°F), with “U” or “K “ values 3 to 6 times higher than shell and tube exchangers

- Easy accessibility

- Range of alloys, including titanium, plus variety of gasket elastomer compounds

Triplex Homogenizing Pump

Benefits

- Sterile processes through absolute asepsis

- High process reliability for 24/7 continuous operation

- Hermetic tightness

- Excellent cleanability

FEATURES

- The LEWA homogenizing pump employs hermetic diaphragm technology, ensuring the utmost production safety for regulated processes and consistently high quality in the final product.

- The LEWA triplex in hygienic design achieves flow rates of up to 18 m3/h or discharge pressures of up to 450 bar.

- For the treatment of delicate fluids, ensuring sterility is of great importance. Leveraging the reliable LEWA triplex pump as a foundation guarantees hermetic tightness in the pump head chamber, preventing emissions into the environment. With extensive experience in the hygienic design of pump heads and operational valves, LEWA ensures the highest level of safety in production, especially when dealing with sensitive fluids. The pump’s exceptional metering precision ensures adherence to recipes and enhances repeatability.

- To meet stringent quality requirements in every process, aseptic pumps from LEWA can undergo qualification and validation, supported by all necessary documentation. Additional advantages of LEWA triplex pumps include a prolonged service life and low life cycle costs.