ANSI PUMPS

magnatex

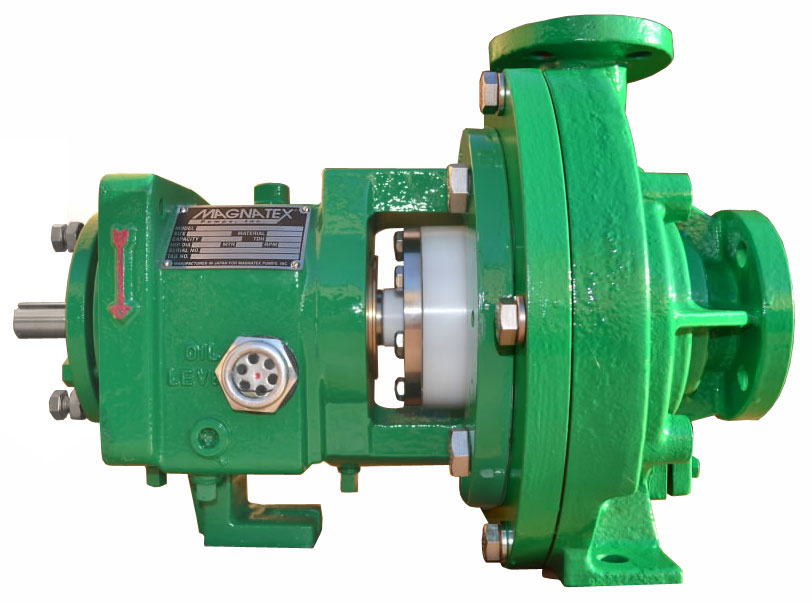

3596

Heavy-duty, rugged, world-class quality, ANSI process pumps manufactured to meet the latest ASME B73.1-2001 standard (revision of ASME B73.1M-1991). The pumps are produced in 29 different sizes, using a diverse range of materials. They provide various seal options and seal flush systems, catering to nearly every application in the process industries.

materials of construction

- Carbon Steel

- 316 SS

- CD4M-Cu

- Alloy 20

- Alloy B&C

- Duplex Stainless Steel

- Ni-Hard

- Titanium

magnatex

mls

The MLS series pumps are robust mechanical seal pumps with ANSI dimensions, featuring PFA/PTFE lining. Specifically engineered for aggressive chemical services, particularly those with entrained solids, these pumps are designed to excel in applications where magnetic drive pumps are not advisable.

The pumps are crafted through a 1200 psi transfer molding process, guaranteeing a consistent, highly dense, low-porosity, and air bubble-free lining. This ensures years of trouble-free service, even in the harshest corrosive environments. The linings are securely anchored by dove-tail grooves, establishing a mechanical bond with the metal armor to prevent any movement or cracking in vacuum or low suction pressure applications.

The MLS pump casing armor enables identical flange loads compared to metal pumps. Fluoropolymer-lined pumps have emerged as the preferred choice for replacing costly exotic alloy pumps in process plants globally.

applications

- Plating Acid

- Hydrochloric Acid

- Hydrofluoric Acid

- Ferric Chloride

- Chlorinated Hydrocarbons

- Pickling Acid

- Chlorinated Brine

- Plating Solutions

- Chlorine Dioxide

- Sodium Hypochlorite