UNIBLOC

Unibloc Hygienic Technologies leads the sanitary industry with precision-engineered positive displacement pumps, Air-Operated Double Diaphragm pumps, and drum pumps.

UNIBLOC

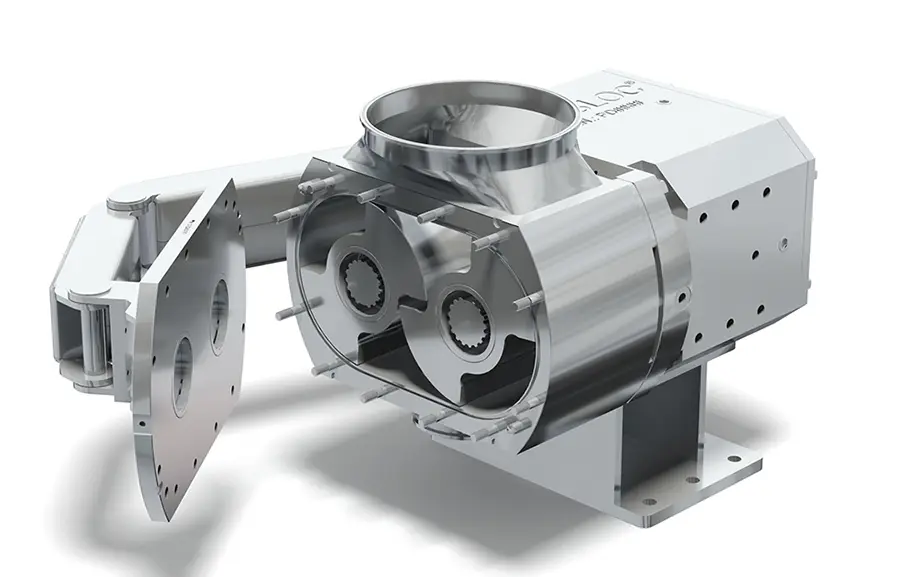

Gear Pump

A gear pump built to last, ensuring worry-free dependability and pinpoint precision. Unibloc’s gear pumps are the premier choice for 3A sanitary applications.

Unibloc Pump’s positive displacement (PD) gear pumps establish a high standard with their robust gearbox design. These pumps deliver a stable platform for accuracy and consistency, offering a wide range of sanitary pumping solutions.Crafted to meet the demands of challenging processing and cleaning environments, Unibloc Pump leads the industry in 3A sanitary applications.

Bearing Housing

Engineered for Precision: Boasts the industry’s strongest precision construction

Material Options: Available in both 316L stainless steel and anodized aluminum

Solid Construction: Each pump head is crafted from solid 316L stainless steel

Compact Design – Short/Stout Shafts

Enhanced Performance: Minimizes refraction at high pressures, leading to increased productivity, better flow, and extended lifespan

Reinforced Shafts: Optional reinforced jacket shafts for added durability

Spiral Cut Gears

Smooth Operation: Ensures pulsation-free flow for quiet and efficient operation

Compatibility: Compatible with servomechanical equipment, offering precise flow rates

QuickStrip® Design

Easy Cleaning: Engineered to meet FDA’s stringent cleaning requirements for daily use

Tool-Free Access: Allows for easy access to pump head and seals without the need for tools

Versatile Options: Available in both Lobe and Gear style pumps

One-Way Assembly: Ensures accuracy and minimizes damage from foreign materials

Optional Front-Loaded Seal Design: Provides access to seals without detaching the pump head

Ultra-Hygienic Design: Seamless and porosity-free design for the industry’s cleanest CIP/SIP capable pump, with a non-stick gearbox exterior for easier cleaning

Sanitary Pump Application Solutions: Ideal for viscous materials such as fats, oils, and glycerin, with versatile Seal Mount (VSM) technology for simplified operations across multiple applications

Material Options: Offered in a variety of industry-specific materials and designs, including rotor material options such as stainless steel alloy, Polyflex® plastic metal detectable, and DuraCore® composite designs, and gear material alternatives including Teflon/Stainless, Teflon, and various plastics.

features

- Ultra-hygienic design

- Precision-built bearing housing

- Compact design

- Smooth, quiet operation

- QuickStrip® design for meticulous cleaning

- Positive Displacement Pump

UNIBLOC

LOBE Pump

With its core boasting a meticulously machined gearbox, this lobe pump establishes new benchmarks in industry performance, offering sanitary solutions tailored to diverse applications.

Unibloc’s lobe positive displacement (PD) pumps establish a benchmark with their dynamic gearbox foundation, offering a robust platform for consistency and precision across a wide range of sanitary pumping solutions.

Crafted to excel in demanding processing and cleaning environments, Unibloc Pump leads the industry in 3A sanitary applications.

Minimized Product Shear: Ensures low-product shear and exceptional displacement

Precise Tolerances: Features tight, no-contact tolerances, with optional non-galling alloy rotors to reduce the risk of foreign material and wear.

ULTRA-HYGIENIC DESIGN

The sleek design eliminates any potential pinches or gaps that could harbor material buildup or harbor hazardous microorganisms. The gearbox boasts a non-stick exterior for effortless cleaning.

features

- Ultra-hygienic design

- Patented rotor for low product shear

- QuickStrip® design for meticulous cleaning

benfits

- Tailored for High Pressure and High Temperature: Ideal for applications requiring high pressure, high temperature, and handling low shear or abrasive products.

- Versatile Seal Mount (VSM) Technology: Simplifies operations across various applications by enabling seals to mount on any pump head without modifications.

- Diverse Material Options: Offered in a range of industry-specific materials and designs.

- Rotor Material Varieties: Options include stainless steel alloy, Polyflex® plastic metal detectable, and DuraCore® composite designs.

UNIBLOC

one-nut pump

The “One-Nut” Sanitary Air-Operated Double-Diaphragm Pump

Flotronic® has gained recognition for its innovative creation, the “One-Nut” Air-Operated Double-Diaphragm pump (AODD). This groundbreaking design facilitates rapid disassembly without the need to disconnect the pump from the process pipework.

Flotronic® One-Nut pumps are capable of transferring a wide array of materials with varying viscosities and solids content. They can effectively handle chemicals, adhesives, cosmetics, beverages, dyes, foodstuffs, paints, pharmaceuticals, and solvents. Our clientele’s products span a broad spectrum, encompassing industrial acids, hand creams, and various food items.