Top Entry vs. Submersible Mixers

What’s the Difference?

At Carl Eric Johnson Co. (CEJCO), we provide high-quality mixing solutions for a wide range of industrial applications. As a proud distributor of Chemineer, Kenics, Greerco, and Prochem, we understand that selecting the right type of mixer is critical for process efficiency, equipment longevity, and overall plant performance.

One of the most common questions we get is:

“What’s the difference between top entry and submersible mixers?”

Let’s break it down.

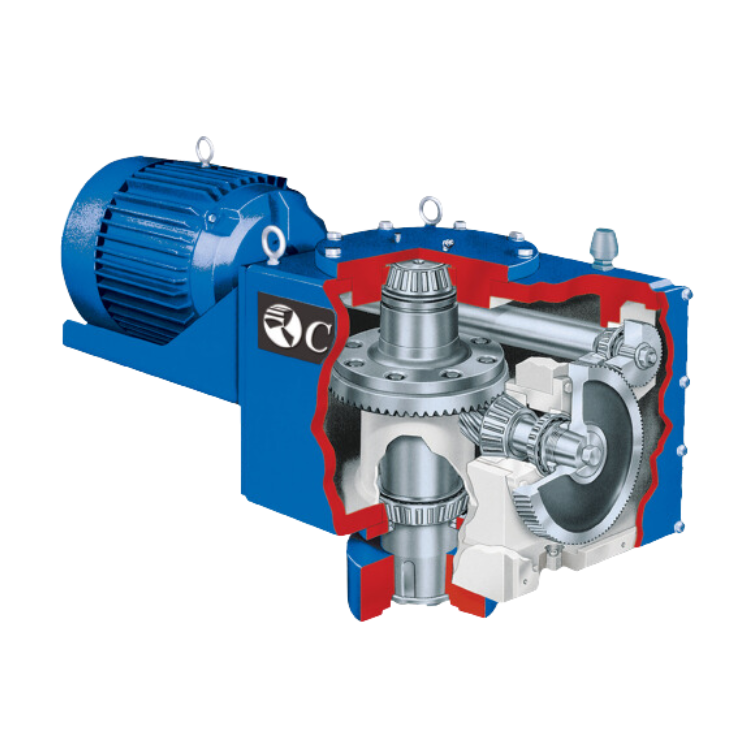

What Is a Top Entry Mixer?

A top entry mixer is mounted vertically at the top of a tank or vessel. It uses a motor-driven shaft and impeller to mix fluids from the top down. Top entry mixers are incredibly versatile and used across industries like water treatment, chemical processing, food and beverage, pharmaceuticals, and more.

Key Advantages:

- Lower energy consumption

- Reduced maintenance and lower long-term costs

- High mixing efficiency for blending, solids suspension, and heat transfer

- Customizable impeller designs and shaft lengths

- Easier access for maintenance and inspection

- Ideal for large-volume tanks and demanding applications

Best for:

- Suspending heavy solids

- High-viscosity fluids

- Applications requiring thorough agitation

- Tanks with vertical access and headroom

Popular models from CEJCO:

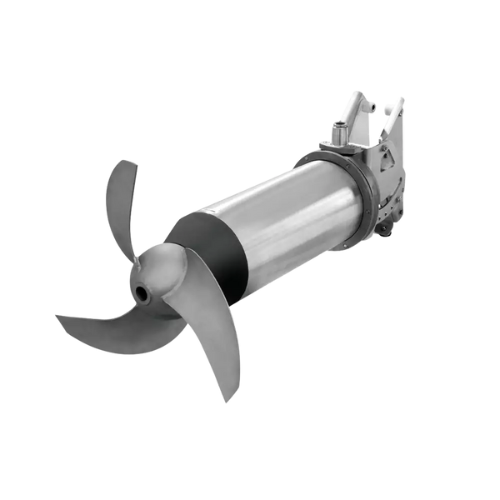

What Is a Submersible Mixer?

A submersible mixer is installed inside the tank and operates while fully submerged in the liquid. These mixers are typically mounted on the side or bottom of the tank and are used to create directional flow for blending or maintaining solids in suspension.

Key Advantages:

- Compact, space-saving design

- Good for mixing in shallow tanks

- Installation does not require a nozzle or bridge structure

Best for:

- Basic wastewater treatment applications

- Non-continuous processes where brief downtime is manageable

- Applications with limited overhead space

How to Choose the Right Mixer?

Choosing between a top entry and submersible mixer depends on several factors:

- Tank size and geometry

- Fluid viscosity and solids content

- Desired mixing intensity

- Available space and mounting options

- Maintenance accessibility

At CEJCO, our team of experts can help you evaluate your process requirements and recommend the right solution. Whether it’s a Kenics static mixer, a Greerco high-shear unit, or a heavy-duty Chemineer or Prochem agitator.

Partner With CEJCO for Your Mixing Needs

With decades of experience and industry-leading partners like Chemineer, Kenics, Greerco, and Prochem, CEJCO is your trusted source for mixing and agitation equipment across the Southeast and beyond.

Ready to find the right mixer for your application?

Contact our team today to request a quote or discuss your system design.